Testing

Bollard Testing

Attis provide bollard testing services for shoreside bollards and mooring assets as well as specialised assessments for ship borne bollards and tow points. The physical surveying and testing of assets is undertaken by trained Attis personnel with the resultant data analysis and calculation being undertaken remotely by experts at Integrity Testing Pty.

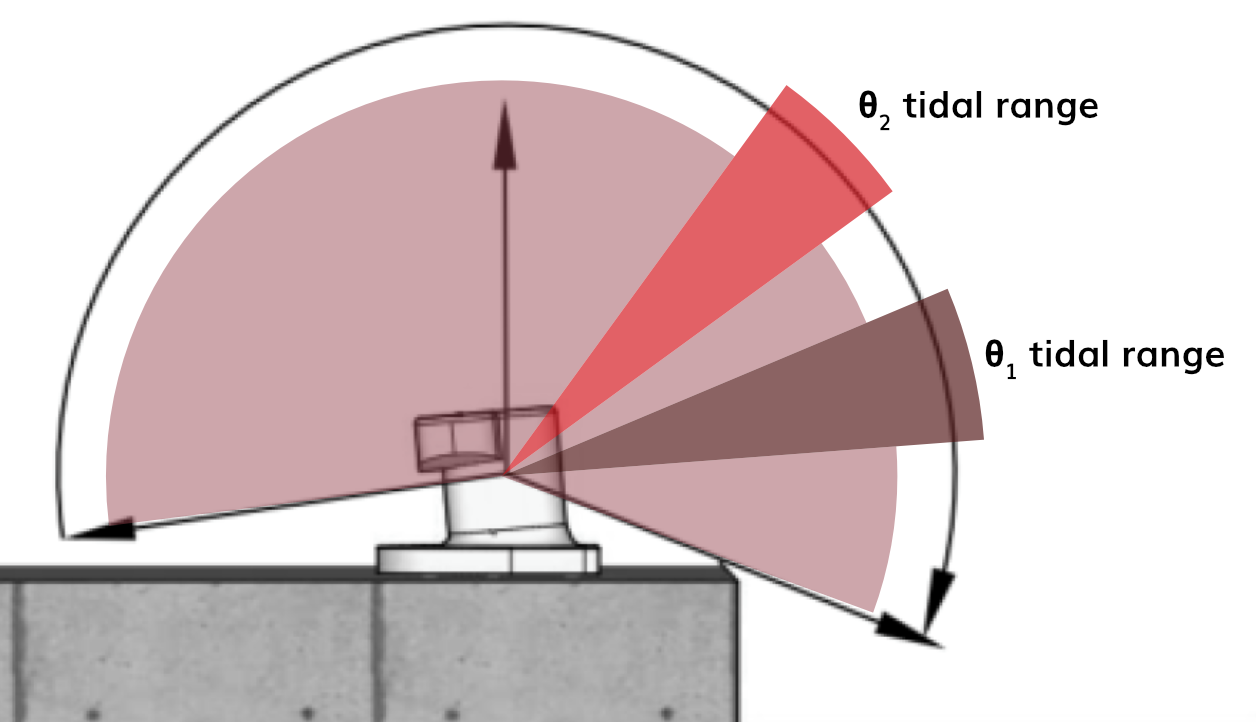

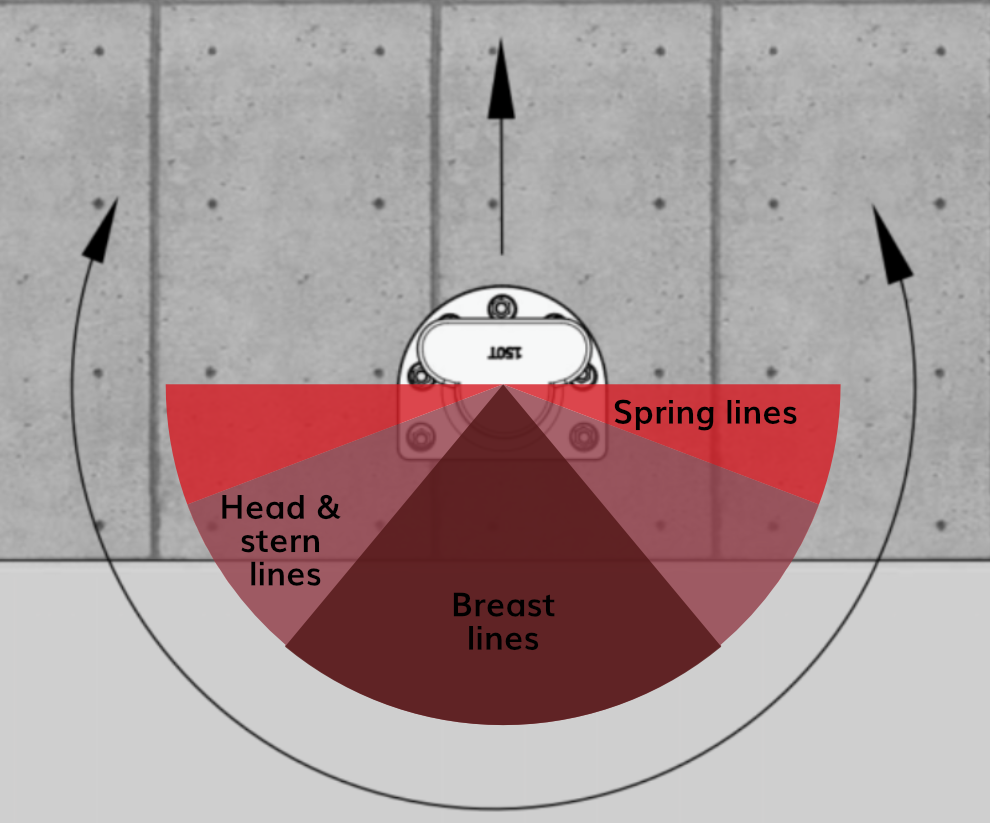

The capacity testing methodology will be orientated to the berth during testing. There is no requirement to lift or move heavy equipment to re-orientate as part of the testing methodology. Each capacity test simultaneously provides empirical data for multiple load angles. This can then be used to produce mooring capacities for various rope angles, vertically as well as horizontally.

Deck Testing

Attis provides deck testing for any surface such as berths, car parks, bridges, buildings and as shown below, even wooden floors in historic buildings.

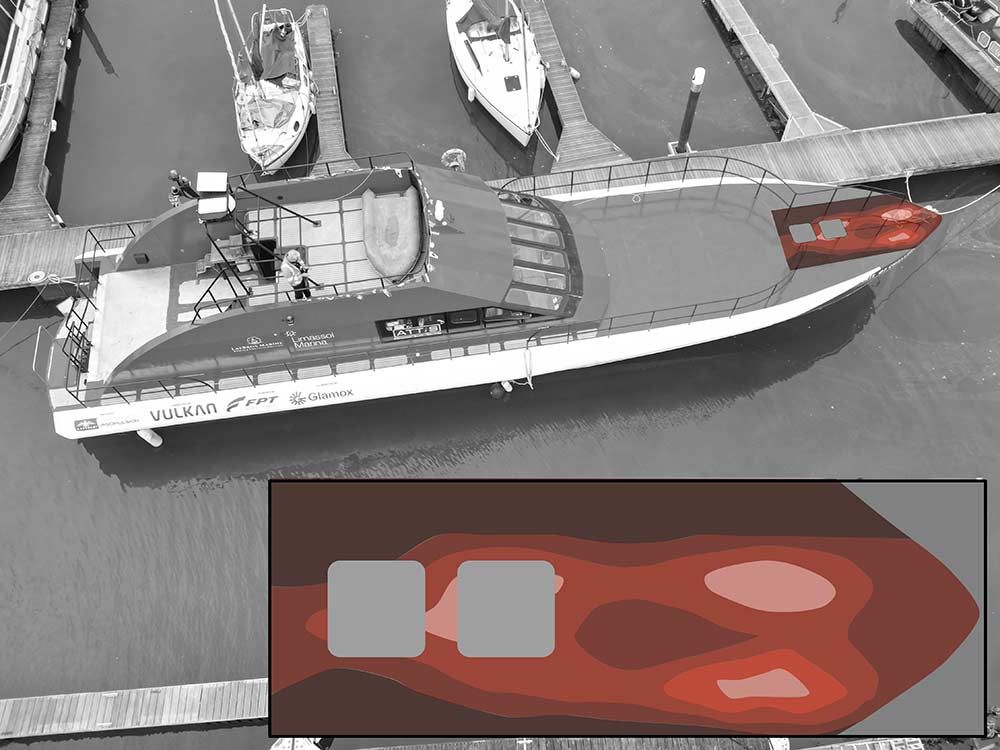

The floor capacity is measured using an array of transducers which, when excited through vibration, measure the amount of deflection. This information is presented as a map of the area showing the recommended maximum loading. This method is unrivalled for identifying weak areas, underground services and voids.

Hybrid Bollard Testing and Deck Structures

Attis provides bollard and towing point testing for maritime vessels using a hybrid test that amalgamates bollard testing with deck testing to provide the angular capacities for the fittings as well as the deck strength. This approach results in a full understanding of how the fitting or towing point will react under load, invaluable information for insurance and other maritime operations..

Why use Attis?

Our non-destructive and non-invasive testing methodology applies an impulse to the asset which is recorded using highly sensitive transducers. There is no need for complicated control measures to reduce the risk of unplanned release of stored energy as no force is applied.

The testing process does not damage the asset or apply undue stress. The results from the test will provide an absolute working capacity in situ which can be used to derate the asset’s SWL if required. If the results show a reduced capacity from initial design, and as long as this reduced capacity allows for operational use, then here is no need for repair or replacement of the asset as the testing methodology leaves it completely undamaged.